A work order is a child work item within an order that needs to be completed internally by an employee in VertiGIS FM. An order cannot be marked as complete until all work orders within it are completed.

Work Order Details

Each work order in VertiGIS FM has its own details page, which you can access by double-clicking a work order in the Work Order section on the details page for another data object or on the VertiGIS FM Maintenance search page.

Each work order is associated with the data points below.

Work Order Details

Work Order Detail |

Description |

|---|---|

Target date |

The date by which the work order should be completed. |

Employees |

The employee assigned to the work order. While the work order should be assigned to an employee, you can assign it to any contact stored in the Contact Management module that has the Maintainer contact type assigned. |

Name |

The name of the work order. |

Planting time [h] |

An estimated number of hours required to complete the work order. |

Description |

A general description of the work order. |

Status |

The current status of the work order (In Progress, Deliver, Finished, Declined). |

Confirmation date |

The date and time the work order's status was changed to Finished. |

Production

If the work order is for a device whose that is in a group whose Production value is set to Yes, the following information is also included in the work order.

Production Details

Work Order Detail |

Description |

|---|---|

Standstill [h] |

A field that, for a work order that is associated with an order that is associated with a ticket, indicates the amount of time from when the ticket is opened until the work order is completed. To enable this functionality, •The work order, order, and ticket must be associated with a device whose group has the Production value set to Yes. •The work order, order, and ticket must be associated with a device whose version has the Add Operational Hours set to Yes. •The work order and order are associated with a ticket that has the Standstill value set to Yes. |

Number of employees stay |

The number of employees impacted by a standstill. |

Used Lock Out / Tag Out |

Whether the machine must be energetically isolated. Information field only. |

Idle time at the maintainer |

How long it takes for items in the group to receive maintenance during downtimes. |

Idle time at the external company |

How long it takes for items in the group to receive maintenance by an external party during downtimes. |

Loss of productivity [h] |

The total number of hours of productivity lost by the stoppage. |

Add a Work Order to an Order

A work order is added to an order on the order details page.

Adding a work order to an order that has a status of Finished causes the parent order to be re-opened.

To Add a Work Order to an Order

1.On the order details page, expand the Work Order section and click the Add (![]() ) icon.

) icon.

2.Under Work Orders, click the Add (![]() ) icon again.

) icon again.

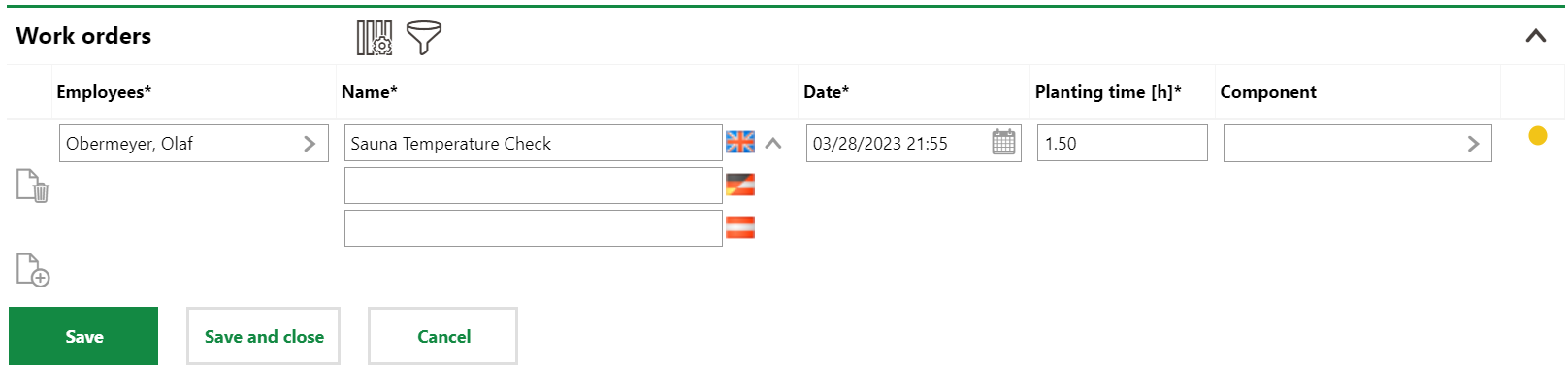

3.Fill out the form fields for the new work order.

▪Under Employees, click the arrow icon (![]() ) and select an employee to assign the work order to. You can select any contact that has the Maintainer contact type assigned.

) and select an employee to assign the work order to. You can select any contact that has the Maintainer contact type assigned.

▪In the Name text box, enter a descriptive title for the work order.

▪The Date field auto-fills with the completion date for the order, but this date and time can be changed.

▪In the Planting time [h] text box, enter the amount of time in hours the work order will take to complete.

▪Optionally, under Components, click the arrow icon (![]() ) and select any components installed on the device that the person completing the work order will need to take with them.

) and select any components installed on the device that the person completing the work order will need to take with them.

4.Click Save and Close.

Adding a work order to an order whose status is Finished re-opens the order (i.e., updates its status to In Progress).

Complete a Work Order

Work orders can be marked as Finished when you edit them.

You cannot edit a work order if it is for a device's whose group's Production property is set to No.

To Complete a Work Order

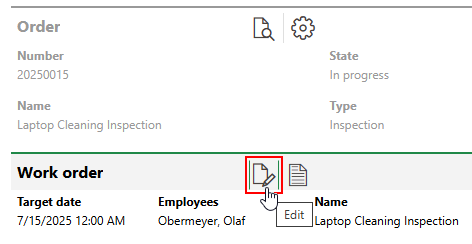

1.On the order details page, select a work item in the Work Order section and click the Edit (![]() ) icon.

) icon.

2.Fill in any of the empty form fields with any relevant details associated with the work order.

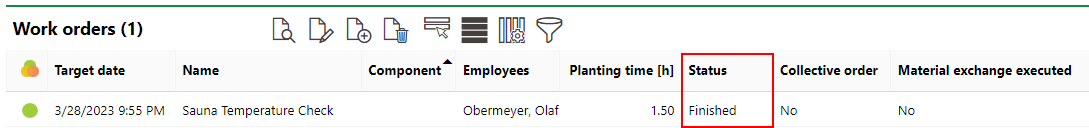

3.From the Status drop-down menu, select Finished. This causes the Confirmation Date field to auto-fill with the current date and time.

4.If an exchange of components was required to complete the work order, select the Material exchange executed check box.

5.Optionally, expand the Time Recording tab, click the Add (![]() ) icon, and, in the Hours text box, enter the number of hours that were required to complete the work order. Refer to Add Time Entries.

) icon, and, in the Hours text box, enter the number of hours that were required to complete the work order. Refer to Add Time Entries.

6.Optionally, if any materials were removed from the device, expand the Add (![]() ) icon, and fill out the required fields to outline the removal of materials.

) icon, and fill out the required fields to outline the removal of materials.

7.Click Save and Close.

The Status column in the Work Order section on the order details page now indicates that the work order has been completed.

Completed Work Order on Order Details Page

Closing the order's last work order or subcontraction that has a status of In progress or Planned changes the order's status to Finished.

Add Time Entries

Time entries indicate a number of hours a maintenance employee in your organization has spent working on a work order. Time entries associated with a given work order are listed in the Time Recording section on the work order's details page.

You can add time entries to a work order when you edit (or as you complete) a work order.

To Add Time Entries to a Work Order

1.Open the work order's edit for by doing either of the following:

▪on the details page for the parent order, select a work order in the Work Order section and click the Edit (![]() ) icon.

) icon.

▪navigate to the work order's details page by double-clicking a work order in the Work Orders section on the details page for the parent order, and then click the Edit (![]() ) icon.

) icon.

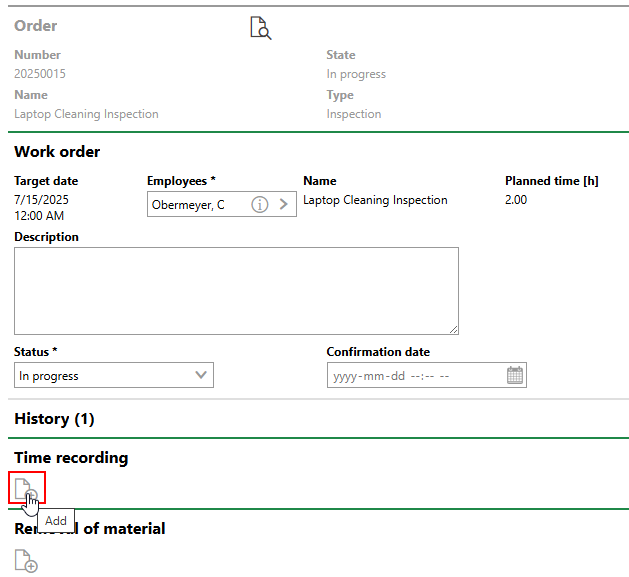

2.Under Time Recording, click the Add (![]() ) icon.

) icon.

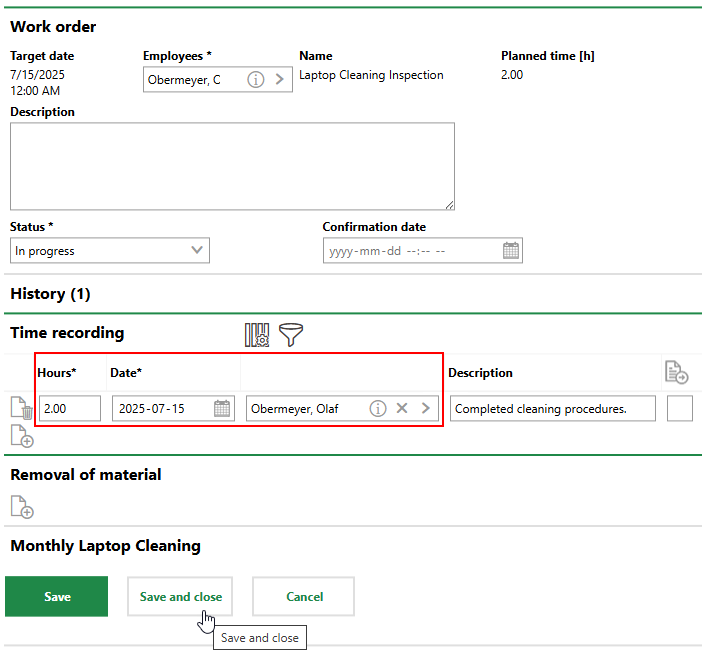

3.In the Hours text box, enter the number of hours worked on the work order.

4.In the Date menu, use the date picker to select the date the work occurred.

By default, your user is selected in the time entry. If your user is assigned a user role with the Time recording for other employees permission (Administration > Roles/Permissions > Role Administration > Time Recording), you can select another employee associated with a contact that has the Maintainer contact type assigned.

5.Click Save or Save and Close.

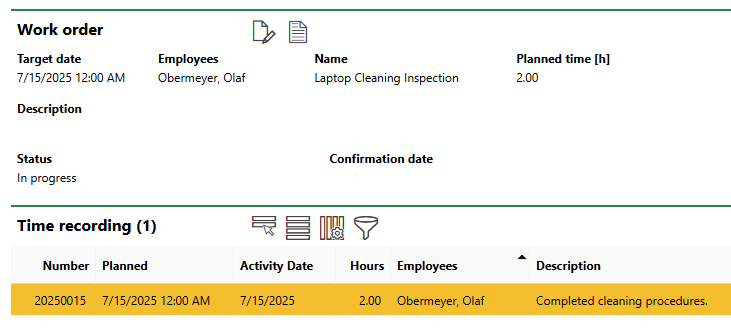

The time spent working on the work order is now documented in the Time Recording section on the work order details page.

Work Order with Time Recording Entry

Settle Orders

You can complete additional work order management tasks on the Settle Work Order workflow. This workflow groups work orders by employee assignment, allowing employees to record time entries for multiple work orders at a time, or to mark multiple work orders as Finished at a time.

Cost Transfer

If time recording entries are saved on a work order, the employee's working hours can be transferred to the Costs and Budget module to generate an internal or outgoing invoice using the Cost Transfer workflow.

Collective Orders

Single work orders can be added to multiple orders. This means a user who completes a task that is required to complete multiple orders only has to mark it as complete once.

For more information, refer to Collective Orders.