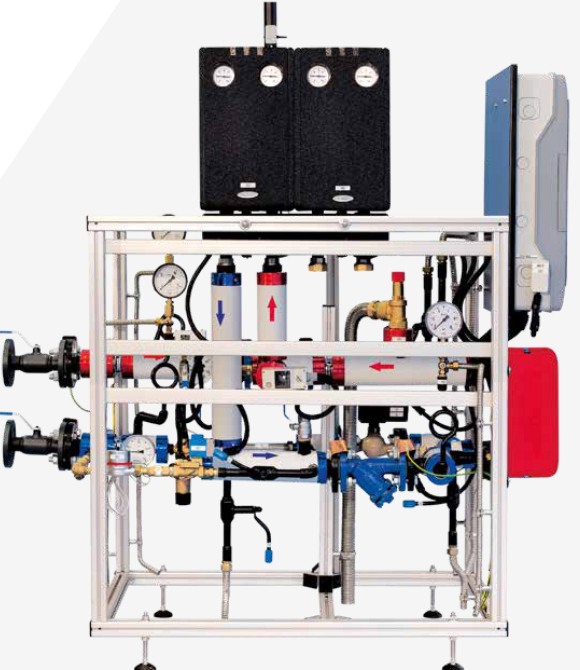

SourceAssembly are used for collection, storage, production or transfer stations.

|

|

|

|

Production plant

This includes all plants that produce or supply district heating or cooling, such as waste incineration plants. This may also include water treatment.

|

|

|

|

|

|

Transfer station

It is the link between two different interconnected hydraulic networks (often primary and secondary networks).

Detailed documentation of the consumer/end customer's home control center is rarely of interest to utility companies. As a transfer point to another proprietary or third-party hydraulic network, documentation of the main elements is important. This station can be used

- for own consumption in the supply network and for energy transmission to another area of the district heating network

- for energy transmission to a customer with their own network (e.g., other heating networks, industrial customers, hospitals, etc.)

As a rule, the energy exchange takes place via a heat exchanger.

|

|

|

|

|

|

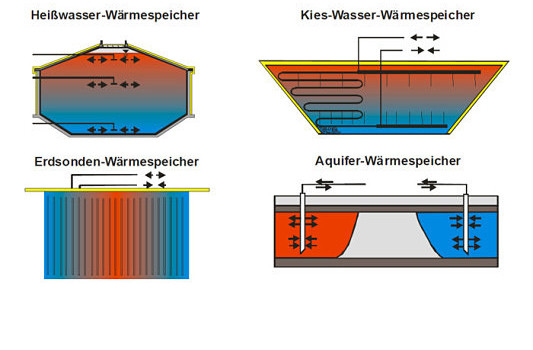

Storage

Energy storage systems store thermal energy so that it can be made available again when needed. There are various types of storage systems:

- Buffer storage: to bridge the time difference between heat production and heat consumption. These are tanks that behave like a boiler.

- Short-term storage: with a storage duration of up to two days, this type of heat storage is mainly used in solar or hot water storage systems to balance heat supply and demand.

- Long-term storage: can be seasonal storage (storing heat in summer and using it in winter, or storing cold in winter and providing it for cooling networks in summer). This also includes ice storage, which, when combined with a heat pump, extracts heat from the water in the ice storage in winter. The water turns to ice, which can then be used to cool rooms in summer.

There are other types of storage that use media other than just water.

|

|