These are all lines which are used for maintenance. The technical terms which are used in the German language area for it are the following:

•Leakage warning systems, leakage monitoring (designation of the entire system incl. sensor and measuring wires)

•Leakage warning wires, signal wires (sensor wire and measuring wire together)

•Reporting veins

Building moisture and leaks cause damage and losses in the network. This means that heat losses, corrosion of pipelines and interruptions in operation are the result of leakage or damage to the jacket pipe. To prevent this, the system is monitored by means of the electrical resistor with two wires.

|

|

|

|

Measuring wire / return wire

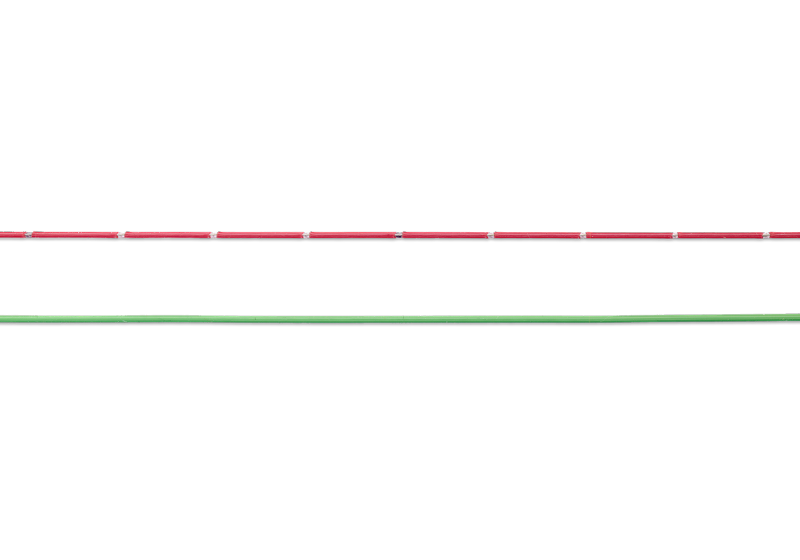

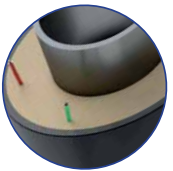

District heating pipes are equipped with two measuring wires embedded in PUR foam. Depending on the system, these are:

Two copper wires (Sn and Cu) with equivalent measuring properties in the Nordic system. The sensor wire is a tinned copper wire. The return wire is a bare copper wire

A Ni-Cr sensor wire and a fully insulated Cu return wire in the Brandes system. The red wire is the sensor wire and is looped into the branches.

Two fully insulated, twisted copper wires (red and white) in the hierarchical system.

|

|

|

|

|

|

Sensor wire

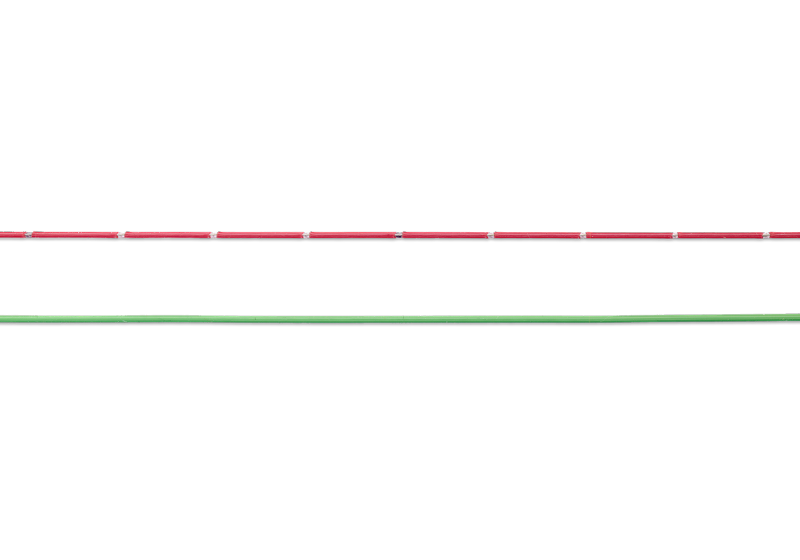

District heating pipes are equipped with two measuring wires embedded in PUR foam. Depending on the system, these are:

- The return wire is the bare copper wire (for Nordic systems or pulse measurement).

- The green wire is the return wire in the Brandes system (resistance measurement)

- Copper wire twisted together with the sensor wire in the hierarchical system (moisture indicator measurement at sleeves)

|

|